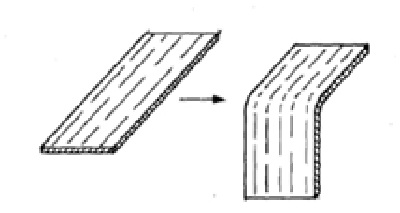

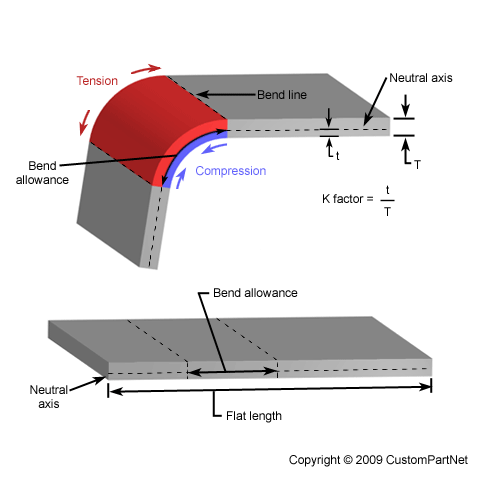

Bending of plates or plate bending refers to the deflection of a plate perpendicular to the plane of the plate under the action of external forces and moments the amount of deflection can be determined by solving the differential equations of an appropriate plate theory the stresses in the plate can be calculated from these deflections.

Bending capacity of steel plate.

What if the material is stainless steel aluminum or brass.

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness.

Clause 11 table 2 special provisions.

We also have small plate rolls for the tight diameters you may need.

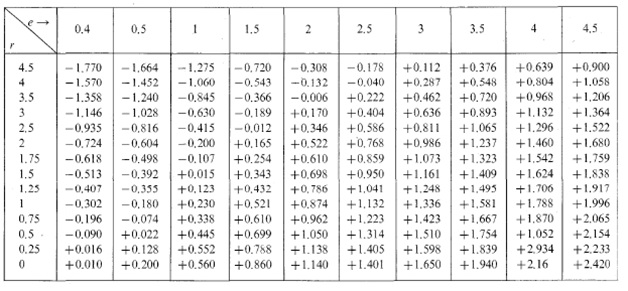

Therefore p 6504 3 4 8 975 kn 99 5 ton the result is very close to the data in the bending force chart.

Plate thickness s 4mm width l 3m σb 450n mm.

Useful in pure bending as well as in beam columns design clauses.

Rolling forming bending is what we are known for and what we do best.

Kubes steel offers the most comprehensive range of technology equipment and capacity to roll form and bend steel sections tubing pipe channel angle and hss in north america.

High definition twin head plasma hi speed plasma flame profiling laser cutting.

We have plate bending capacity up to 20 on both shear and press brake.

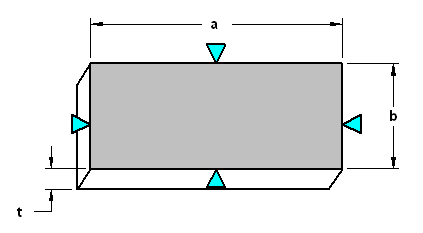

Generally slot width v s 8.

Can csa s16 bending strength as per clauses 13 5 6 7 shear strength as per clause 13 4 local buckling check.

At other points there are biaxial stresses in the plane of the plate.

Once the stresses are known failure theories can be.

As you can see method 1 to calculate the press brake tonnage is based on the mild steel material.

Hornsby steel has tons of plate capabilities.

We also have shear and press brake capability up to 3 4 x.

In steel between 0 5 and 0 8 in.

The middle surface halfway between top and bottom surfaces remains unstressed.