Bending the galvanized steel can help you mold it into shapes appropriate for your project.

Bending 0 135 galvanized steel sheet.

Plate but the principle is the same.

This is done through the application of force on a workpiece.

That s technically sheet metal and a long way from 0 5 in.

It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

As an example if you want to bend 24 gauge sheet metal at a 90 angle the calculation would be.

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

2450 x 1225 x 0 8 mm.

The minimum inside bend radius is even larger when bending with the grain.

We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.

Bending is one of the most common sheet metal fabrication operations.

2450 x 1225 x 0 5 mm.

2450 x 1225 x 0 6 mm.

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

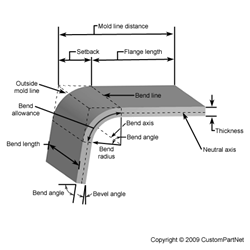

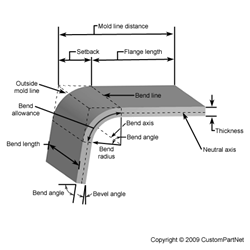

As this happens you gain a small amount of total length in your part.

Material bend radii and minimum bend size charts please note.

Sheet plate sold in full sheets steel pipes galv sheeting.

Figure 3 shows 10 gauge 0 135 in material.

In steel between 0 5 and 0 8 in.

Astm a 143 recommends the minimum bend radius for any part that will be hot dip galvanized after bending be at least three times the material s thickness.

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

The force must exceed the material s yield strength to achieve a plastic deformation.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

2450 x 1225 x 1 2 mm.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Abn sheet metal hand seamer 3 inch straight jaw manual metal bender tool sheet metal bending pliers flattening tool 4 5 out of 5 stars 137 27 89 27.

This allows for some cold work in the bend area without causing.

Galvanized steel is a resilient and corrosion resistant metal which makes it an ideal component in many projects.

The material will need to be lifted during forming over a 1 125 in.

The bending process is fairly simple but you should feel confident operating power tools before you attempt to bend the galvanized steel.

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.