The bend radius refers to the inside radius.

Bend angle tolerance sheet metal.

We will start by calculating the bend allowance.

However minor differences from coil to coil and from the beginning of the coil to the end are possible.

The main reason different die angles exist in air bending is not to bend different angles but instead to allow the punch to descend far enough into the die space to overbend for springback.

Bends can be short or long depending on what the design requires.

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length.

Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees.

From there we can calculate the k factor and the bend deduction.

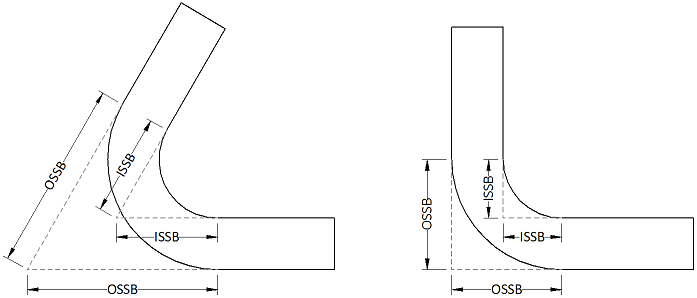

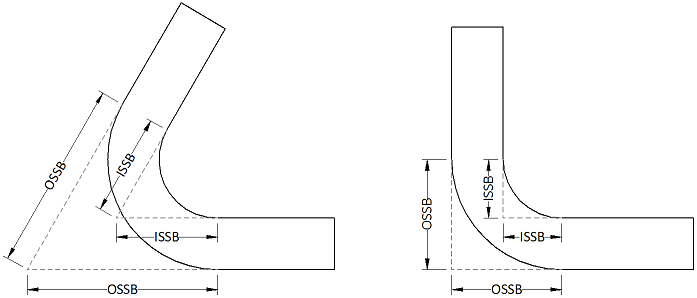

Geometry of tooling imposes a minimum bend dimension.

The metals industry typically does a great job of controlling metal specs.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Press brake bend length 0 010 0 25mm per bend for controlled dimension.

Bending is performed by a press brake machine that can be automatically or manually loaded.

Bend angle 1 degree.

The bend allowance describes the length of the neutral axis between the bend lines or in other words the arc length of the bend.

Folder bend length 0 010 0 25mm per bend for controlled dimension.

The formed bend radius is dependent upon the dies used the material properties and the material thickness.

Refer to the chart for values for folder as well as various press brake tooling combinations.

The bend deduction is the amount the sheet metal will stretch when bent as measured from the outside edges of the bend.

What determines an air bent bend angle is the relationship between the width of the die opening and the depth of penetration into the die space.

Bending is a process whereby a force is applied to sheet metal which causes it to bend at an angle and form the desired shape.

The sheet metal bending height should be at least 2 times the thickness of the sheet metal plus the bending radius that is h 2t r.

After bending the sheet we need to do some measurements as shown in figure 2.

Bend length 0 010 0 25mm.