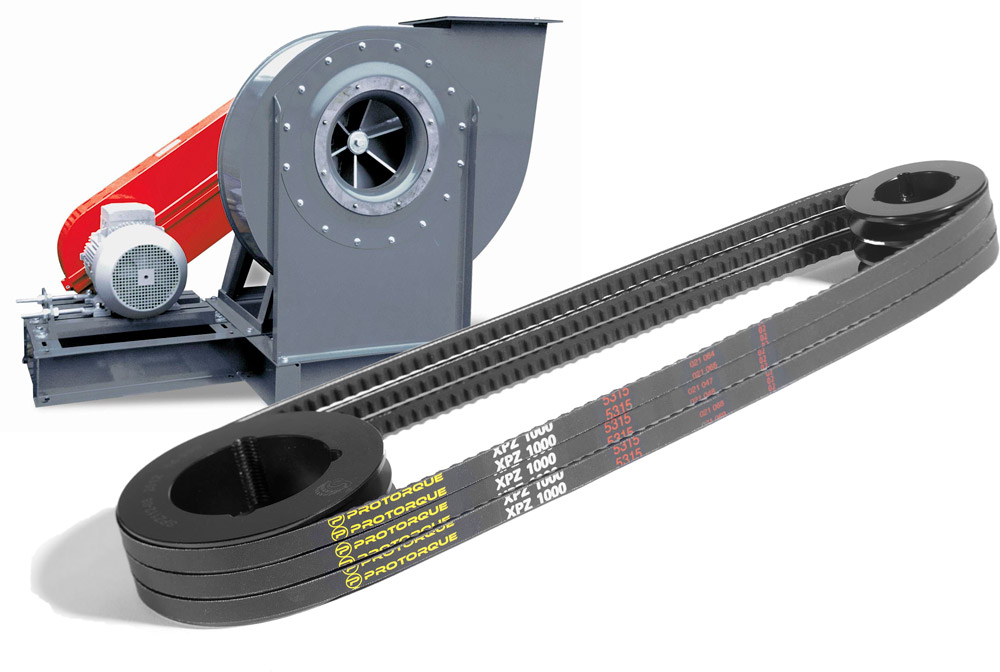

Vibration analysis is a condition monitoring test which is widely applied for determining the operating condition of any rotating machine for example centrifugal fan.

Belt driven fan vibration.

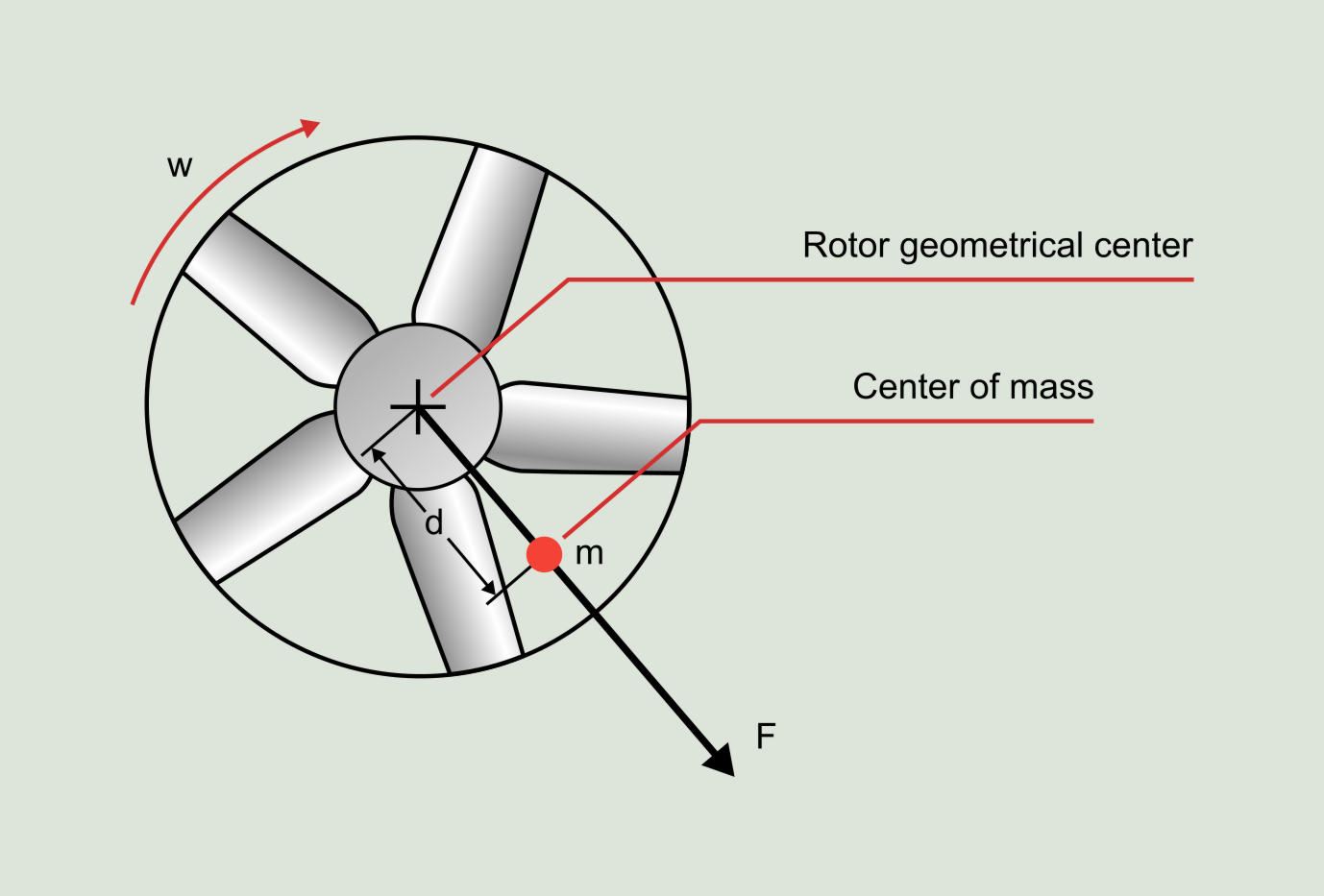

Most vibration was at the fan shaft rotational frequency.

Eccentric pulley on the fan causes vibration at 1x rpm of the fan.

In this report we will have to discuss problem of vibration for one centrifugal fan with the help of the vibration analysis technique.

Fatigue type failure in fan components due to continued exposure to abnormal loads or vibration.

Loosening of hardware on the fan or deterioration of the structure and hardware supporting the fan.

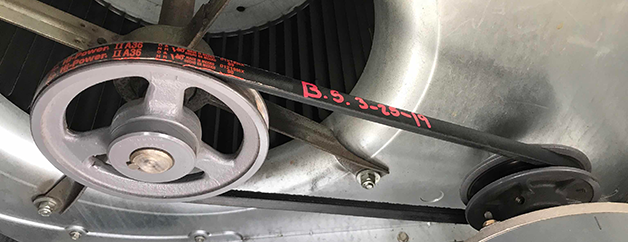

It is important to realize that some of the belt drive vibration problems listed above do not cause vibration at belt related frequencies.

While belts require very little maintenance improper belt tension misalignment of pulleys mishandling of belts and environmental factors are common problems that can shorten the life of your belts and bring your system to a halt.

Problems due to the shafts or pulleys misalignment eccentricity etc cause vibration at 1x rpm of the component with the problem i e.

Both axial readings were in phase at running speed as determined by cross channel phase readings.

It can be confirmed by measuring phase in the axial direction at fan speed.

This vibration pattern is not typical for a belt drive.

Sheave misalignment is a very common problem with belt driven fans.

The axial vibration levels were high but slightly different on each bearing.

Belts along with electric motors shafts and pulleys are a critical component of power transmission in belt drive systems.